Quality

Providing the highest product quality

Profiles are our passion – which also goes hand-in-hand with top quality, because what matters to us more than anything is to be a reliable and permanent partner for our customers.

We justify the trust that our customers place in Welser Profile with extensive quality assurance measures along the entire supply chain, all of which are anchored in the management system of Welser Profile. This guarantees that we achieve the same standards at all production sites!

Your benefits:

- High competence in testing and measurement technology

- Own, well-equipped testing lab for material tests in-house

- Strong involvement of our customers in the processes with high transparency, e.g. in audits

- Comprehensive management system which covers quality as well as environment, energy and health & safety

- Many licenses issued by external certification bodies to cover a wide range of customer/industry requirements

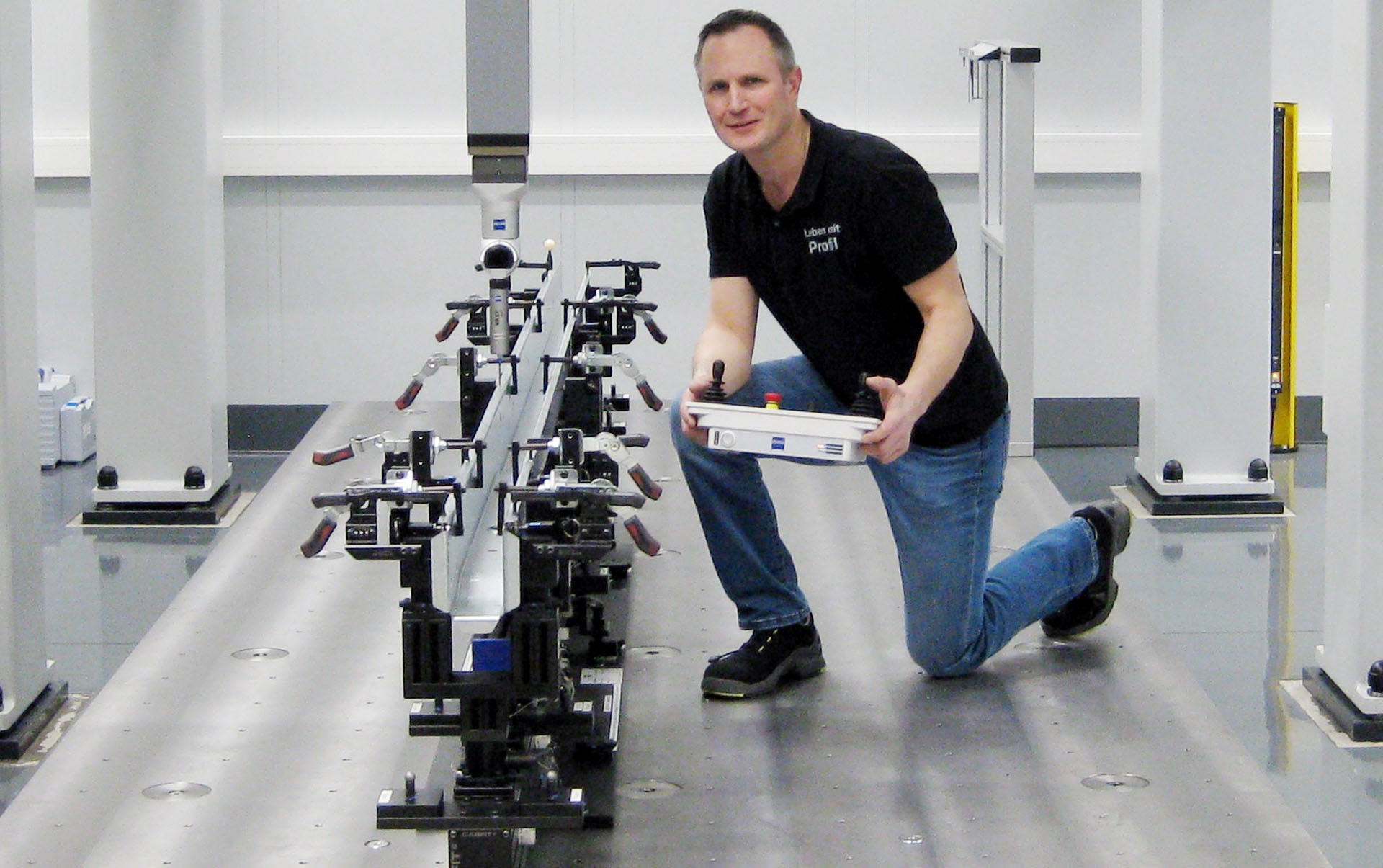

Quality assurance

We are also happy to involve our customers in the quality assurance processes, such as the approval of initial samples on site. Regular system, process, product, and supplier audits, modern measurement methods as well as the permanent training and development of our employees ensure the highest quality standard of the company, which is certified pursuant to ISO 9001 (since 1995) and IATF 16949, among others.

When it comes to quality assurance, other technologies are used in addition to standard test equipment if required. These include, for example:

- Tactile 3D coordinate measuring technology

- 3D laser measurement technology

- Camera systems in special test facilities (process integrated)

- Product-specific inductive measurement technology

We use both destructive and non-destructive methods for testing welded profiles and assemblies. Here we rely on eddy current testing, thermography and laser triangulation.