Advanced roll forming

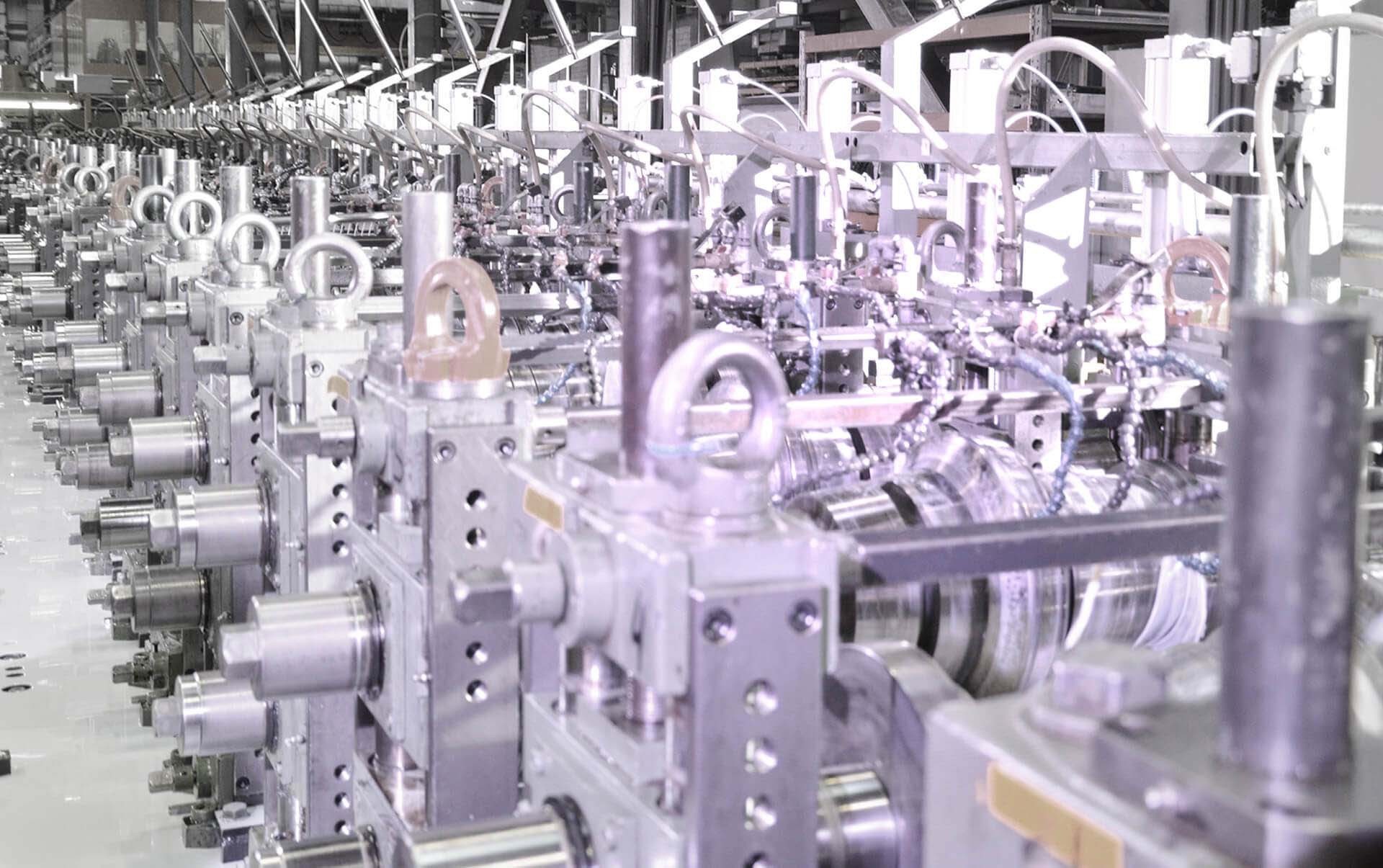

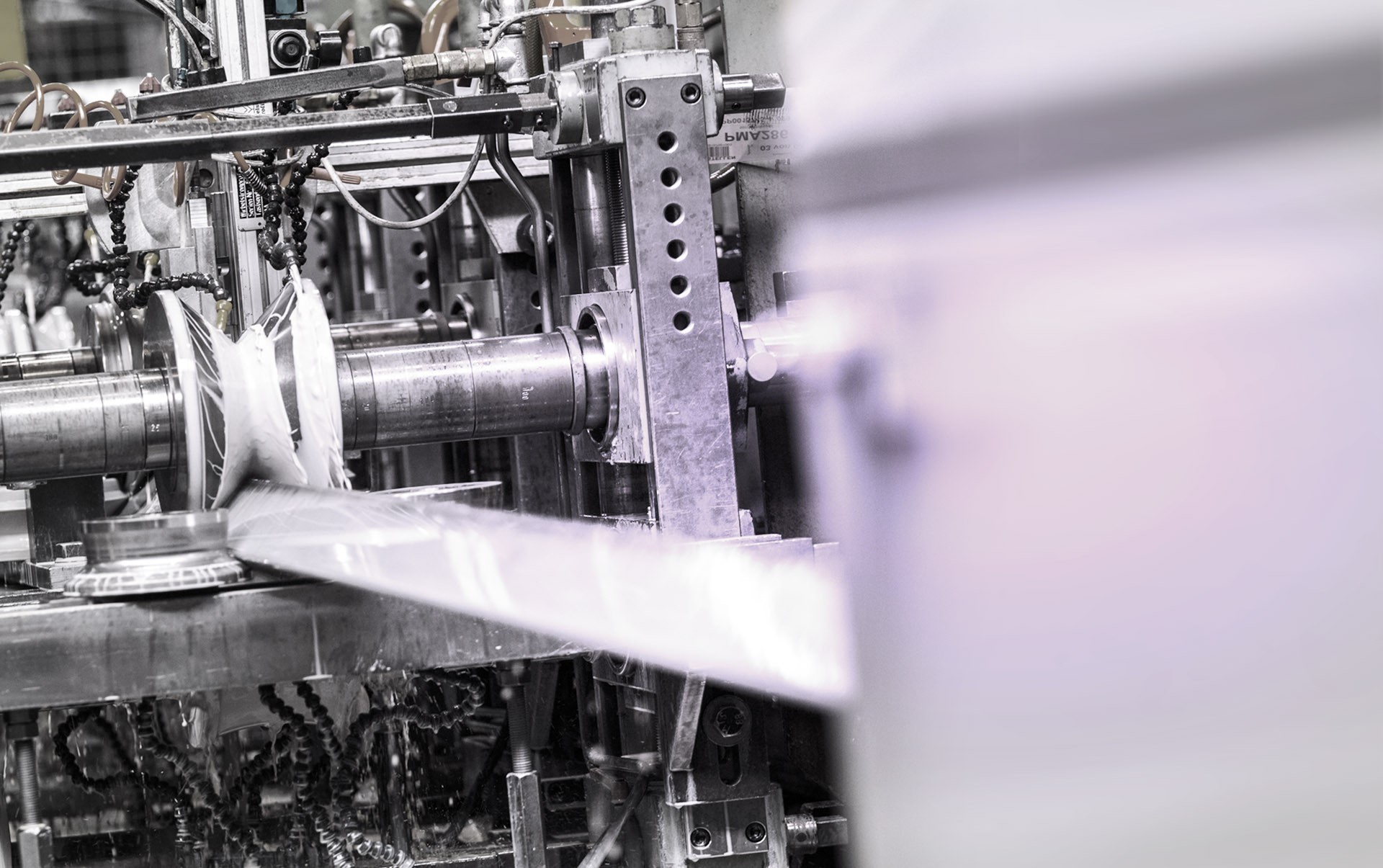

The more complex the requirements for the profile cross-section, the more we are in our element. That underscores the fact that most of our profiling systems have been perfected through in-house development, and that the processes themselves are also constantly being optimized. The result is cross-sections that are variable in all dimensions.

Profiles optimized for strip thickness

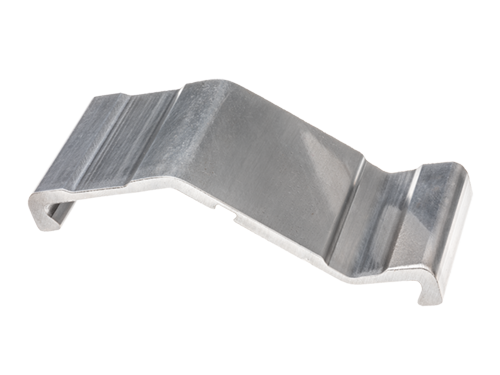

In traditional roll forming, the properties of the profiles are primarily achieved by selecting the material with the necessary sheet thickness and through the design of the shape. We have added a decisive parameter to these possibilities: variable material thickness. We enable a load-optimized design of the profile through calculated reduction of the strip thickness or clinching the split strip, preferably near or on the edges of the strip.

That means: while we used to have to base the material thickness of the overall profile on the maximum thickness required, we are now able to achieve a load-optimized design. We thin the material in those areas where it is not needed as a way to reduce the overall weight.

ADVANTAGES

- Weight saving

- Improvement of existing and integration of new functions (grooves, optimizing the quality of the weld seam, etc.).

- Optimizing the mechanical properties: increasing the surface hardness and thus, for example, improving the service life of running surfaces, multiple pullouts or telescopic profile tubes. Greater strength makes profiles capable of carrying more and therefore withstanding greater loads.

- New possibilities of visual design: e.g. different design of opposing surfaces.

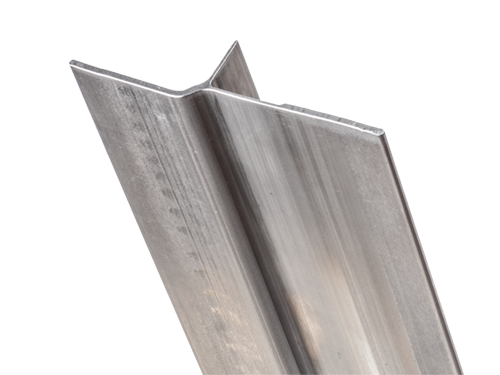

Linear flow splitting, linear bend splitting, and varying cross-sections

Flexibility with regard to cross-section, load adaptation or joining possibilities is increasingly being requested.

With linear flow splitting, linear bend splitting and the production of profiles with varying cross-sections, we offer even more room for ideas and solutions to problems.

Advantages

- The reshaped material becomes harder, smoother and more resistant to wear and tear.

- New possibilities for joining other profiles, e.g. spot welding at the freestanding tabs; the indentations produced can be used for bonding material.

- Functional enhancements, e.g. through the incorporation of closed profile chambers (so-called cavity profiles), which are used as installation space in support profiles or are able to absorb impact forces in vehicles.