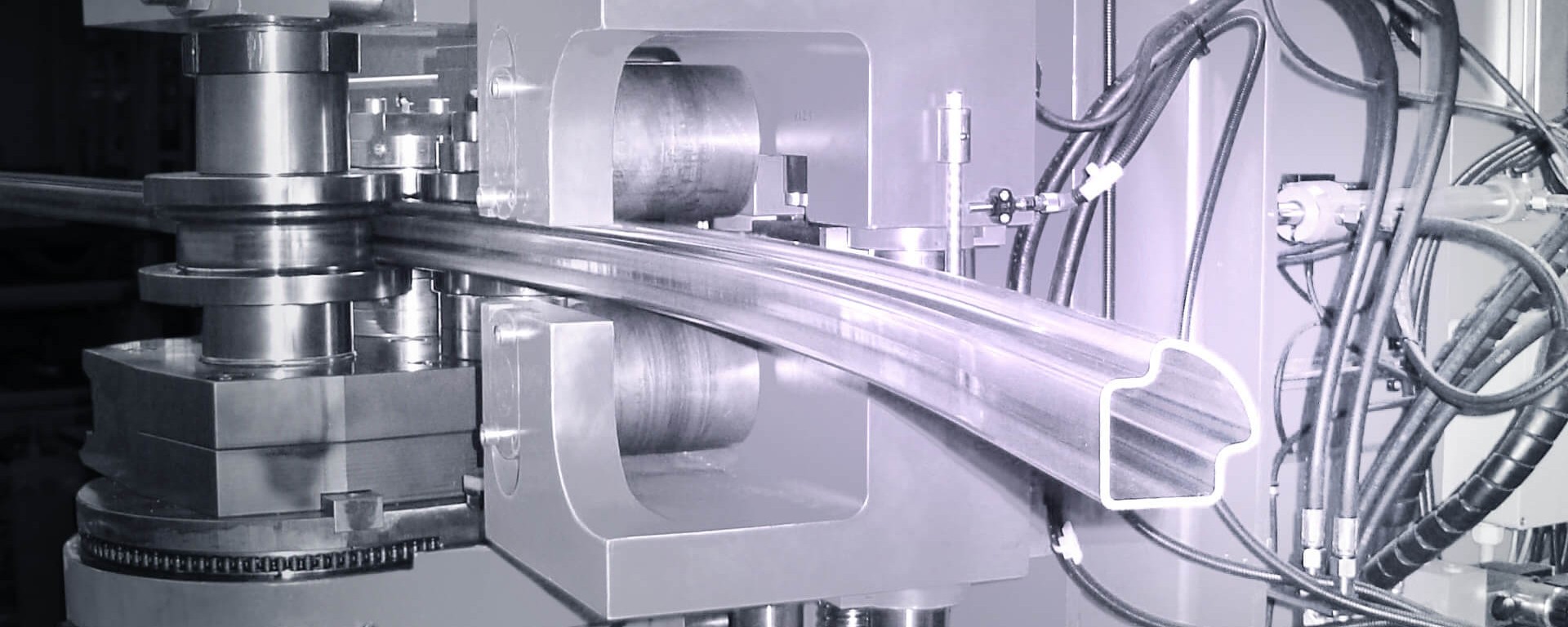

Steel section bending

We bend and finalize “ready to use”

Many years of experience and the knowledge acquired through the manufacturing of bent custom profiles, modern state-of-the-art machinery, and high quality standards are the factors for success that ensure our economical production concepts in the area of profile bending technology. Our aspiration for the future is to optimize these concepts for smaller runs.

Expertise

Our advantage:

- Bending parts made from a wide range of materials – common structural steels, high-strength and stainless steels – with countless different cross-sections (open/welded, asymmetrical/symmetrical, HF/laser welded, thin or thick-walled)

- Flawless quality, even at high degrees of shaping – parts geometry, surface

- Tightest bending radii

- High dimensional accuracy and fit for efficient further processing in your company

- 3-dimensional bending

The in-house tool shop brings us increased flexibility. We combine simulation technology, tool design based on this, and finally the tool production itself – all under one roof. In this way, unnecessary tool adjustment cycles can mostly be eliminated in advance.

Competence in technology

What’s more, all technologies available at Welser can be used for the development of customized integrated components. In this way, we want to support our customers even better with difficult projects and offer the very best solution from each available technology.

Variety of applications

Our steel profiles, which are sometimes designed for the tightest bending radii and tolerances, are used in a wide range of industries. These extend from automotive, freight wagon construction, cabin construction and agricultural equipment to components for the health and leisure industry, to profiles for building and municipal technology.

Know-how of employees

Our well-trained production staff have many years of experience in bending technology and work constantly on improving processes and tool concepts. Regular CIP projects require and promote new ways of thinking that won’t permit any stagnation of the technology.